Fire damper roll forming machine brief.

The fire damper roll forming machine is a complete production line for manufacture of damper with slotted assemble holes . It is made from light gauge steel thickness from 1.0-1.5mm . The roll formed fire damper is a technical profile which can fold and joint together with hands or simple tools.

The fire damper roll forming machine is a cost-effective complex production line.Including pre-punching and notching ,post-cutting ,servo feeding and optional with various kind of value added devices.

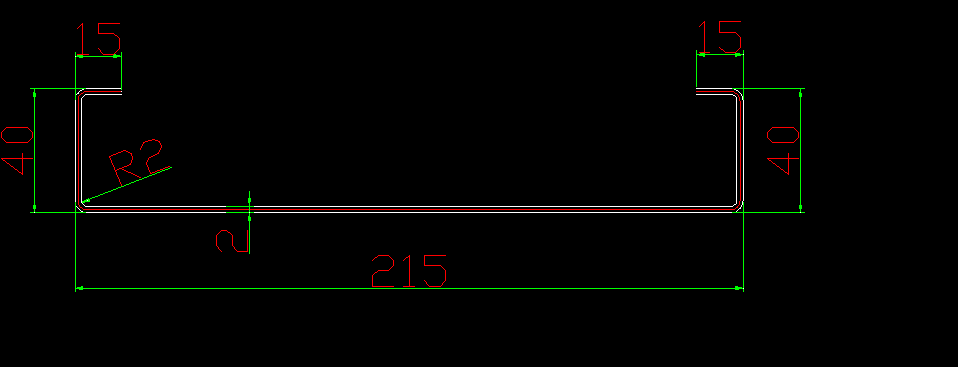

Reference profile drawing for fire damper roll forming machine :

Working process of fire damper roll forming machine :

Starts from the unwinding of metal coils , entry the multi-press punching devices after servo feeding,notch the edge and assemble holes, then entry the main fire damper roll former ,roll formed to size according to client’s design , cut to length by hydraulic cutting device ,fold the frame and close the frame by fasten the notched connector by simple tools.

Decoiling—servo feeding —punching—roll forming —hydraulic cutting—-folding—stacking

Layout of fire damper roll forming line

The standard whole solution on the fire damper roll forming line is combined of uncoiler , hydraulic punching device,stationary hydraulic shear device, main fire damper roll former,run out table .

| Machine Component | quantity |

| Decoiler | 1 set |

| Servo feeder | 1 set |

| Hydraulic punching device and punching die | 4 set |

| Main fire damper roll former | 1 set |

| Hydraulic cut device with hydraulic station | 1 set |

| PLC Control system | 1 set |

| Run out table | 2 sets |

VCD damper frame roll forming machine parameter

| Suitable material | Coil type | Galvanized Steel | |

| Coil Thickness | 1.0-1.5 mm | ||

| Coil Width | According to design | ||

| Yield Strength | 250-350Mpa | ||

| Decoiler | Decoiler Type | Hydraulic | |

| Weight Capacity | 3 Ton | ||

| Punching and notching | Punching type | Hydraulic punching | |

| Punching sets | 2-3 punching stations according to profile | ||

| Hydraulic station | About 30 Mpa main motor power 7.5 KW | ||

| Main Roll Forming | Forming Station | 16 forming stations, depend on profiles | |

| Roller Material | GCcr15, surface with hard chrome 0.05mm | ||

| Shaft Material | #45 high strength steel quenched 55-60 degree | ||

| Shaft Diameter | 68 mm | ||

| Drive Type | 1.2 Inc Chain drive | ||

| Forming Speed | 5-12m/min | ||

| Main Power | 7.5 KW | ||

| Cutting Device | Cutting Type | Hydraulic cutting | |

| Cutting Die Material | Cr12Mov | ||

| Cutting Tolerance | +/-1mm(10m) | ||

| Hydraulic station | 7.5KW , share one hydraulic station with punching | ||

| Folding device | Folding type | Hydraulic folding automatic control by PLC | |

| Folding stage | 4 stage | ||

| Electrical System | PLC Brand | Panasonic | |

| Inverter Brand | Yaskawa | ||

| Encoder | OMRON brand | ||

| Touch Screen | MCGS, china top brand | ||

| Electrical parts | Schneider | ||

| Motors Reducer | Tailong and Guo mao Chinese famous brand | ||

| Run out table | Table Type | No power passive with rollers | |

| Function of Table | To support the profile sheets after cutting | ||

| Machine | Dimension | 8000mm*1000mm*1200mm Around 6000 kg | |

| Tolerance | Length | 3M+/- 1.5mm | |

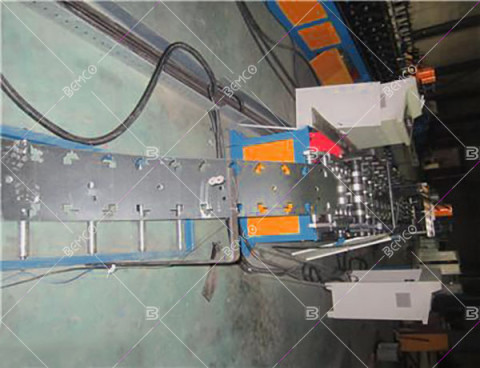

VCD damper frame roll forming machine (picture original taken in factory)

Order Enquiry Form

Contact form description text