What is roll forming ?

Roll forming is a common and cost-effective metal profile manufacturing method , it is widely used technology almost every where into our life. Have a ever wondered how the slide track on your sliding door is manufactured ? Or which machine can make the shutter door lath ? Every buildings , vehicle, container , agriculture , industry, roll forming as a classic metal process way still plays a very important character even in the future.

How does roll forming machine work ?

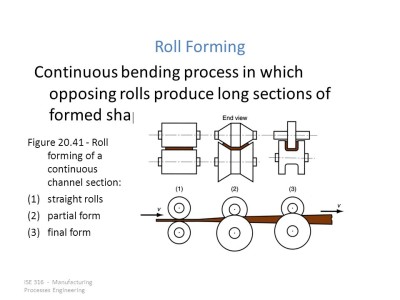

The roll forming machine bends flat metal strip with numbers of roll forming stations ,each station have up and bottom rollers and sometimes side guide rollers. When passing through the stations, the metal sheet changing shapes a little more than previous station, till the flat sheet finished with the correct cross-section. It is a continuous processing of bending.

Cold roll forming is a continuous shape processing of metals.The purpose of the roll forming process is to make the desired section metal profile from flat metal strip.It is a continuous, efficiency, cost-effective metal bending operation .The shapes of the metal sheet changing when passing through a bunch of matching pairs of contoured rolls and finally get your desired shapes.The acting machine is called the roll forming machine, or roll former.

Below is the simple picture about roll forming process:

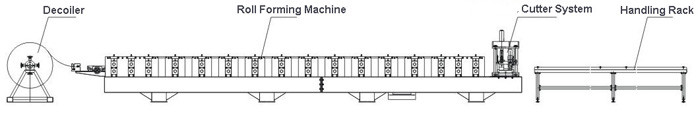

The roll former is the simplest roll forming line, which is integrated by different kinds of components.Below is a typical and simple example:

- Decoiler

- Main roll forming machine

- Shear device ( stationary or follow )

- Product run out table

A complete roll forming line can be integrated with many value-added equipment such like welder , press machine, and other secondary operation equipment, these equipment can be designed in-line process together with the whole production line or off-line , the roll forming line is a cost-effective and flexible metal processing solution.