Strict Quality Control during all the manufacturing process of roll forming machine

“Quality is the blood of one company”is the spirit that deeply mark into every staff of Bemco machinery.

Since the day we begin our first roll forming machine, the machine quality is as the most important principle of this company, quality is just like the blood and running through all the process of machine’s manufacturing.

1 .Bemco only select quality raw material from famous and reliable supplier. The base of the machine is always welded from high strength H beam profile from Shanghai Baosteel group. And the surface powder coated with NOBEL or DUPONT Nontoxic paint, it ensured the durable and stable performance of product and also environmental protection. All the shafts or the roll tooling is CNC from ASTM 1045 and heat treatment quenched to HRC 48-52 , the roll tooling rollers is AISI 52100 and with heat treatment and chromed 0.05 mm,all the roll tooling is precision processed by CNC machine.

2. Bemco has excellent machine tools to ensure the quality and tooling accuracy of all the products.

Bemco always use advanced equipment to make sure every component made by ourselves efficiency and quality .we have a regularly plan to improve and increase our equipments to keep us in a leading position of industry.

3. Bemco has a mature QC team with strict quality control rules.

Over 10 year of experience on the manufacturing of top lever quality roll forming machine,and almost of the roll former are exported all over the world. every one in our QC team is familiar with the most standards in the world like CE and ISO…

Our quality is also benefit from the efforts of continuous improvement :

- SOP -Standard Operation Procedure

- F&A- feedback and action ,test and get feed back , analysis and action plan

- Six sigma

- Workers training

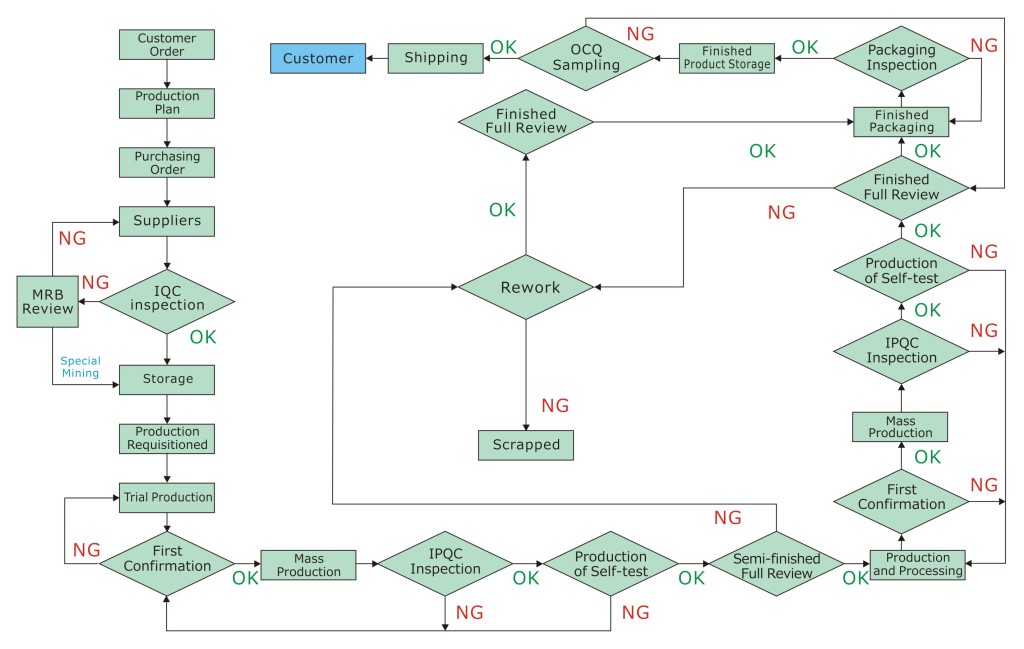

Our QC process is as below:

Raw material inspection by purchasing Dep. → Inspection after raw material cutting by Manufacturing Dep. → “Next” producing-process inspect “last” step during manufacturing by worker and Manu. Dep → Raw product inspection before powder coating by Manu. Dep. → Inspection before packing by QC Dep. → Final inspection before shipment by QC Dep. →Final equipment debug by technical staff→Final safety check by QC Dep→ Third part inspection by individual organization or customer