K span roll forming machine brief.

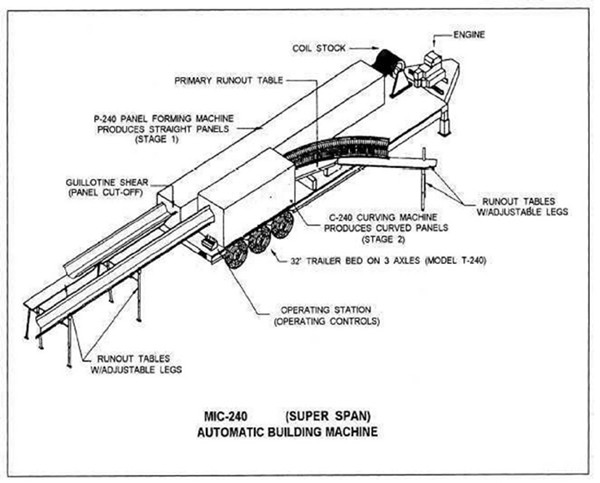

The K span roll forming machine is a on-site roll forming machine for the manufacturing of metal span roof for arch building. The k span roll forming machine is a mini factory on wheels that can produce durable steel arch building in days rather than weeks or months. The k span roll forming machine contain of a panel roll forming machine, a panel curving device, engine power unit, control system and trailer to transit to everywhere.

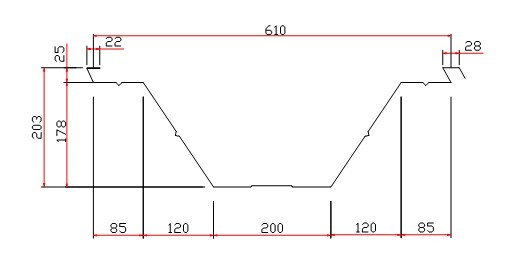

The standard profile drawing for k span roll forming machine

The k span roll forming machine working process :

The k span roll forming machine is starts from the unwinding of metal coils,entry the k span panel roll forming machine after leveling , then roll formed to panels , cut to length by hydraulic cutting device, then curve the panels to certain radius,all the power can be supported by the engine power unit mounted on the k span roll forming machine.

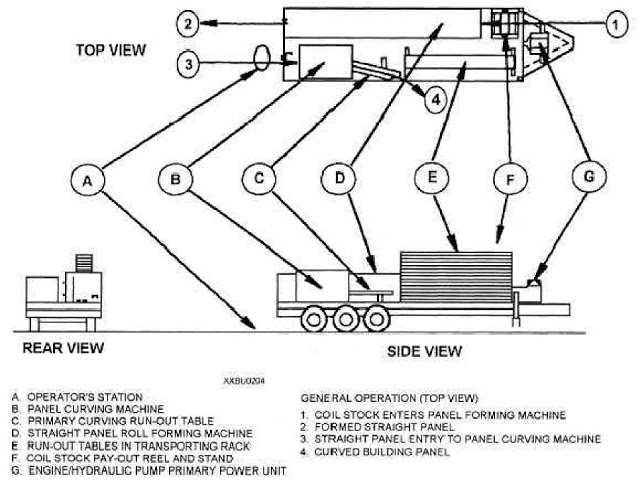

Decoiling—guiding& leveling —roll forming—-hydraulic cutting—-storage area—curving—run out table

Layout of k span machine

The whole solution on the k span roll forming machine is combined of uncoiler , stationary hydraulic shear device, main k span roll former,panel storage rack,panel curving device, engine power unit,control system and a trailer.

| Machine Component | quantity |

| Decoiler | 1 set |

| Trailer | Optional |

| Engine power unit (generator) | Optional |

| Hydraulic cut device with hydraulic station | 1 set |

| Main k span roll former | 1 set |

| Control system | 1 set |

| Panel storage racks | 1 set |

| Panel hydraulic curving device | 1 set |

| Curved panel run out table | 1 set |

MIC 240 K span machine parameter

| Suitable material | Coil type | Galvanized Steel or color coated steel | |

| Coil Thickness | 0.6-1.5mm | ||

| Coil Width | 914mm | ||

| Yield Strength | 250-550Mpa | ||

| Decoiler | Decoiler Type | Passive | |

| Weight Capacity | 5 Ton | ||

| Punching (optional) | Punching type | Hydraulic punching | |

| Punching sets | 2-3 punching stations according to profile | ||

| Hydraulic station | About 30 Mpa main motor power 7.5 KW | ||

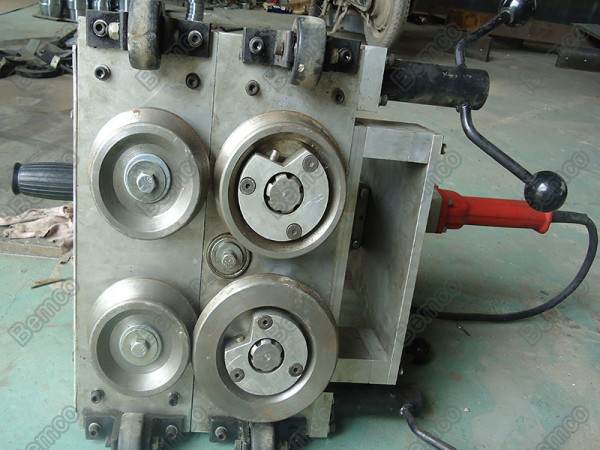

| Main Roll Forming | Forming Station | 13-15 forming stations, depend on profiles | |

| Roller Material | CR40, surface with hard chrome 0.05mm | ||

| Shaft Material | #45 high strength steel quenched 55-60 degree | ||

| Shaft Diameter | 60-75 mm | ||

| Drive Type | Chain drive | ||

| Forming Speed | 5-12m/min | ||

| Main Power | 7.5 KW | ||

| Cutting Device | Cutting Type | Hydraulic cutting | |

| Cutting Die Material | Cr12Mov | ||

| Cutting Tolerance | +/-1mm(10m) | ||

| Hydraulic station | 7.5KW , share one hydraulic station with punching | ||

| Curving device | Curving power | 4.0+1.5+1.5 kW | |

| Electrical System | PLC Brand | Panasonic | |

| Inverter Brand | Yaskawa | ||

| Encoder | OMRON brand | ||

| Touch Screen | MCGS, china top brand | ||

| Electrical parts | Schneider | ||

| Motors Reducer | Tailong and Guo mao Chinese famous brand | ||

| Run out table | Table Type | No power passive with rollers | |

| Function of Table | To support the profile sheets after cutting | ||

| Machine | Dimension | 11000mm*2500mm*2500mm Around 11000kg | |

| Tolerance | Length | 3M+/- 1.5mm | |

MIC 240 super span machine (picture original taken in factory)

Order Enquiry Form

Contact form description text