Project general information

-

Project Date:2015-12-1

-

: Project Lead time: 100 days

-

Project rate: Hard

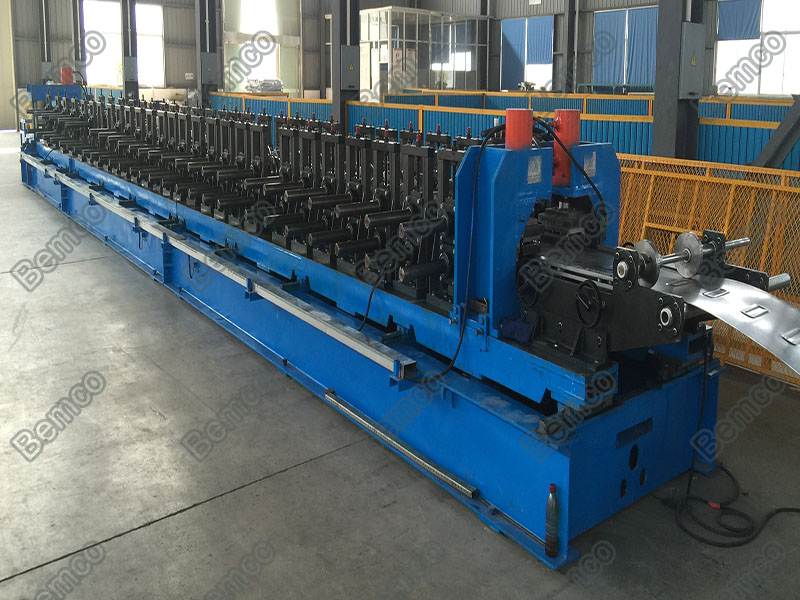

This is one project showcase of our custom cable tray roll forming line for our domestic client– for Nuclear station , one group company , this roll forming line is well received and now running perfectly in their factory. This roll forming line is very complex with very large punching press units and heavy duty gauge and high strength steel .Contact us for more design details on the complex roll forming line , please send us your specification via sales@bemcomachinery.com , challenge our capacity !

The main technical parameter of this cable tray roll forming line.

| Suitable material | Coil type | Galvanized Steel | |

| Coil Thickness | 0.5-3.0 mm | ||

| Coil Width | According to design | ||

| Yield Strength | 350-550Mpa | ||

| Decoiler | Decoiler Type | Hydraulic | |

| Weight Capacity | 5 Ton | ||

| Punching | Punching type | Hydraulic punching or punching press machine | |

| Punching sets | 2-3 punching stations according to profile | ||

| Hydraulic station | About 30 Mpa main motor power 7.5 KW | ||

| Main Roll Forming | Forming Station | 20 forming stations, depend on profiles | |

| Roller Material | GCcr15, surface with hard chrome 0.05mm | ||

| Shaft Material | #45 high strength steel quenched 55-60 degree | ||

| Shaft Diameter | 90 mm | ||

| Drive Type | Gearbox Drive | ||

| Forming Speed | 5-8m/min | ||

| Main Power | 22 KW | ||

| Cutting Device | Cutting Type | Hydraulic cutting | |

| Cutting Die Material | Cr12Mov | ||

| Cutting Tolerance | +/-1mm(10m) | ||

| Hydraulic station | 5.5 KW , share one hydraulic station with punching | ||

| Electrical System | PLC Brand | Panasonic | |

| Inverter Brand | Yaskawa | ||

| Encoder | OMRON brand | ||

| Touch Screen | MCGS, china top brand | ||

| Electrical parts | Schneider | ||

| Motors Reducer | Tailong and Guo mao Chinese famous brand | ||

| Run out table | Table Type | No power passive with rollers | |

| Function of Table | To support the profile sheets after cutting | ||

| Machine | Dimension | 16000mm*20000mm*1500mm Around 8000kg | |

| Tolerance | Length | 3M+/- 1.5mm | |