Project general information

-

Project Date:2015-10-1

-

: Project Lead time: 70 days

-

Project rate: Hard

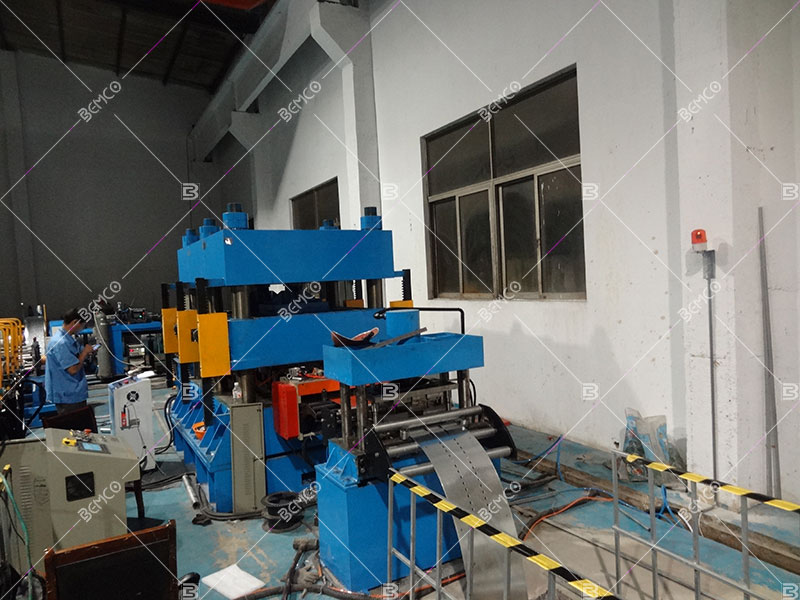

This is one project showcase of our customized roll forming line for our demestic client– for frame usage , this roll former is well received and now running perfectly in their factory. This roll forming line is integrated with in-line punching and saw cutting .Contact us for more design details on the complex roll forming line , please send us your specification via sales@bemcomachinery.com , challenge our capacity !

The main technical parameter of this customized roll forming line.

| Suitable material | Coil type | Galvanized Steel | |

| Coil Thickness | 0.4-0.7 mm | ||

| Coil Width | According to design | ||

| Yield Strength | 350-550Mpa | ||

| Decoiler | Decoiler Type | Manual | |

| Weight Capacity | 3 Ton | ||

| Punching | Punching type | Hydraulic punching and notching | |

| Punching sets | 3 punching stations according to profile | ||

| Hydraulic station | About 16 Mpa main motor power 7.5 KW | ||

| Main Roll Forming | Forming Station | 24 forming stations, depend on profiles | |

| Roller Material | GCcr15, surface with hard chrome 0.05mm | ||

| Shaft Material | #45 high strength steel quenched 55-60 degree | ||

| Shaft Diameter | 45 mm | ||

| Drive Type | Chain drive | ||

| Forming Speed | 8-12m/min | ||

| Main Power | 5.5 KW | ||

| Cutting Device | Cutting Type | Hydraulic cutting | |

| Cutting Die Material | Cr12Mov | ||

| Cutting Tolerance | +/-1mm(10m) | ||

| Hydraulic station | 7.5 KW , share one hydraulic station with punching | ||

| Electrical System | PLC Brand | Panasonic | |

| Inverter Brand | Yaskawa | ||

| Encoder | OMRON brand | ||

| Touch Screen | MCGS, china top brand | ||

| Electrical parts | Schneider | ||

| Motors Reducer | Tailong and Guo mao Chinese famous brand | ||

| Run out table | Table Type | No power passive with rollers | |

| Function of Table | To support the profile sheets after cutting | ||

| Machine | Dimension | 10000mm*800mm*1000mm Around 7000kg | |

| Tolerance | Length | 3M+/- 1.5mm | |