Baffle ceiling tile roll forming machine brief.

The baffle ceiling tile roll forming machine is a single roll former for the manufacture of U shaped channel profile for the baffle ceiling system popular in every market . It is usually made from light gauge aluminum as “V”,”C” or U .

The baffle ceiling tile roll forming machine is a cost-effective and smart machine, it can change sizes by spacers without changing any tools to make various sizes to meet the requirement from client.

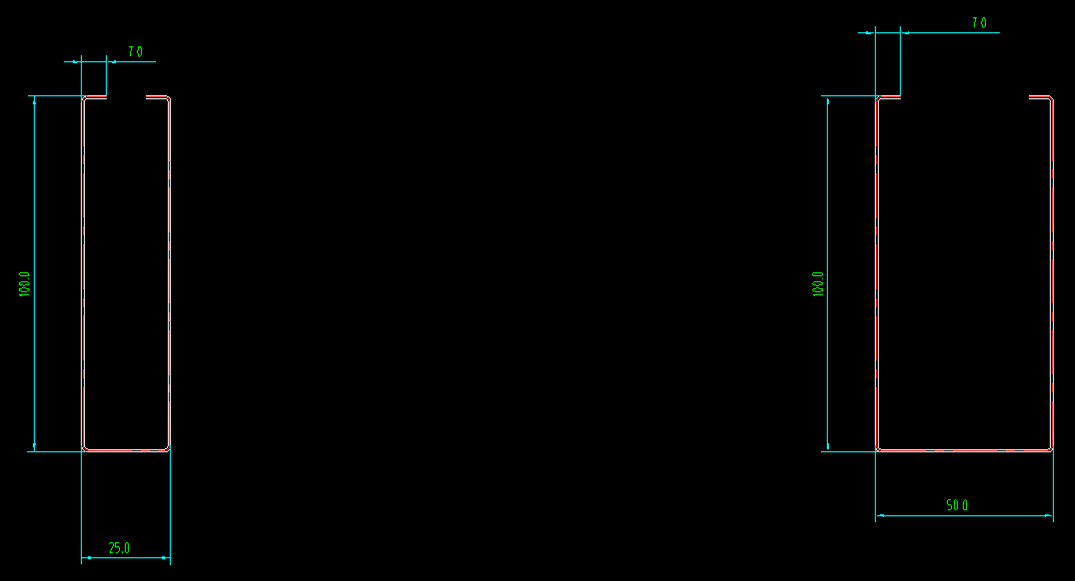

Standard profile drawing for barrel ceiling tile :

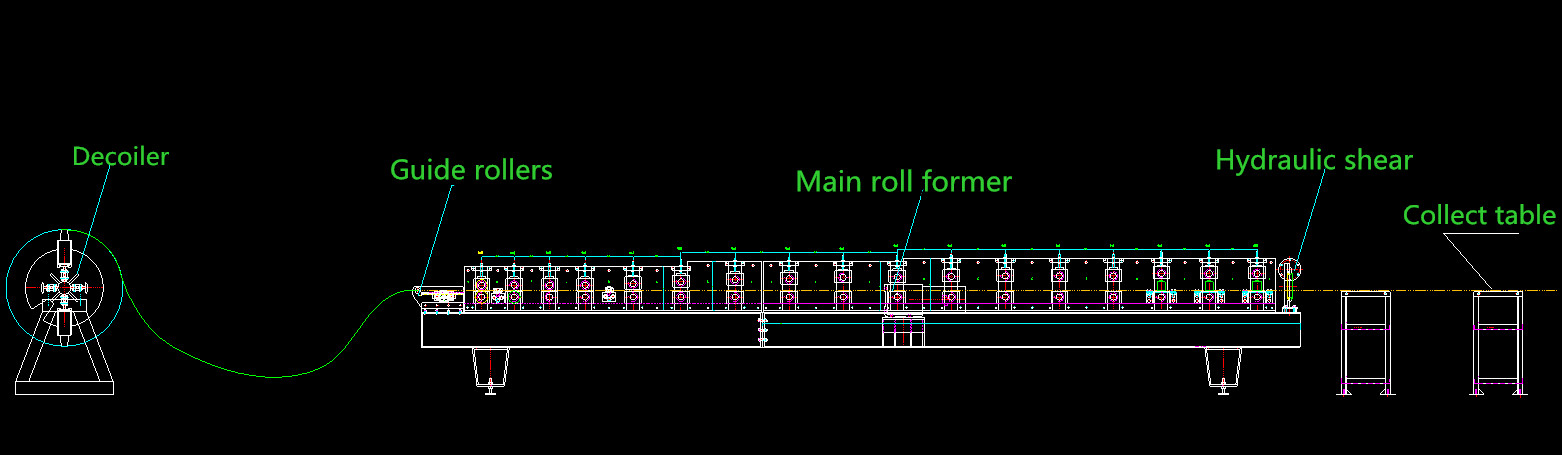

The basic U shaped ceiling tile roll forming process :

The U shape ceiling tile roll forming is starts from the unwinding of metal coils , entry the main roll forming equipment after pinching rollers, then roll formed to U shape profile and size according to client’s design , cut to length by hydraulic cutting device then stack& packing.

Decoiling—guiding&leveling —roll forming —hydraulic cutting—-stacking

Layout of carrying baffle ceiling tile roll forming line

The standard whole solution on the baffle ceiling ceiling tile roll forming line is combined of uncoiler , stationary hydraulic shear device, main ceiling tile roll former,run out table .

| Machine Component | quantity |

| Decoiler | 1 set |

| Guide & pinch rollers | 1 set |

| Main roll former | 1 set |

| Hydraulic cut device with hydraulic station | 1 set |

| PLC Control system | 1 set |

| Run out table | 2 sets |

Baffle ceiling tile roll forming line parameter

| Suitable material | Coil type | Aluminum |

| Coil Thickness | 0.5mm-0.7 mm | |

| Coil Width | Customized according to profile | |

| Yield Strength | 250-350 Mpa | |

| Decoiler | Decoiler Type | Manual or hydraulic |

| Weight Capacity | 3Ton | |

| Main Roll Former | Forming Station | 13-16 forming stations, depend on profiles |

| Roller Material | High grade #45 steel , surface with hard chrome 0.05mm | |

| Shaft Material | #45 steel quenched 55-60 degree | |

| Shaft Diameter | 60 mm | |

| Drive Type | Chain Drive | |

| Forming Speed | 0-20m/min | |

| Main Power | 7.5 KW | |

| Cutting Device | Cutting Type | Hydraulic cutting |

| Cutting blade material | Cr12 with heat treatment | |

| Cutting Tolerance | +/-1.5mm(3m) | |

| Electrical System | PLC Brand | Panasonic brand |

| Inverter Brand | Yaskawa | |

| Encoder | OMRON brand | |

| Touch Screen | MCGS Chinese famous brand | |

| Electrical parts | Schneider | |

| Motors Reducer | Tailong and Guo mao Chinese famous brand | |

| Hydraulic System | Hydraulic Station | Famous Chinese Brand |

| Hydraulic Power | 4 KW with 12 Mpa pressure | |

| Run out table | Table Type | No power passive with rollers |

| Function of Table | To support the profile sheets after cutting | |

| Machine | Dimension | 4500mm*600mm*800mm Around3000kg |

| Tolerance | Length | 3M+/- 1.5mm |

Baffle ceiling tile roll forming line (Picture taken in factory)

Order Enquiry Form

Contact form description text