Coil loading car:

1. Structure: 4-wheel walk, carbon steel welded

2. Power: hydraulic motor BM3-195

3. Lifting: hydraulic cylinder drive Φ180×700mm

4. Lifting distance: 700mm

5. Max. Load: 15000kg

Double-mandrel uncoiler:

1. Type: moving bidirectionally, expanding and contracting inside

2. Expand and Contract drum: driven by sliding block

3. Specification: Φ458-Φ508mm, Φ560-Φ610mm, Φ760-Φ820mm

4. Expand and Contract cylinder: Φ140×75mm

5. Movement power: driven by hydraulic cylinder Φ125×900mm

6. Coil centering:

7. Braking: Pneumatic pressure

8. Applicable coil width: 300-1250mm

9. Max. applicable coil O.D.: 1800mm

10. Max. applicable weight: 15000kg

Coil head drawing, shoveling and feeding device:

1. Draw frame structure: steel welded, lifting driven by hydraulic cylinder

2. Cylinder specification: Φ80×500mm with 2 pieces

3. Driving rolls: Φ300×600mm, coated with Nitrile Butadiene Rubber

4. Driving power: 3KW Cycloidal motor

5. Shovel structure and type: iron plate welded

6. Lift power: hydraulic cylinder Φ80×400mm

7. Expand and contract power: hydraulic cylinder Φ63×400mm

8. Feeding machine structure and type: iron plate welded, opposite rolls pinch and feed

9. Feeding rolls specification: Φ140×1400mm

10. Feeding rolls material: down rolls 40Cr, hard chrome plating; up rolls coated with rubber

11. Feeding rolls lift cylinder: Φ80×100mm, 2 pieces

12. Feeding power: 4KW cycloidal reducer coordinating with universal joint

13. Hydraulic shearing machine: 3×1300mm with 1 piece

Guiding device:

1. Stands structure and type: steel plate welded, standing rolls rectify, double rolls feed

2. Standing rolls specification: Φ125×125mm, 3 pairs, high frequency quench

3. Feed rolls specification: Φ100×1350mm

4. Feed rolls lift power: hydraulic cylinder Φ80×100mm

5. Guiding power: manual control

6. Guiding range: 300-1300mm

Slit head:

1. Structure and type: Cassette type disc shear

2. Slitting shaft specification: Φ200×1350mm (blade position)

3. Slitting shaft material: 40 Cr, forging and tempering, mid-frequency quenching, hard chrome plating, grinding

4. Disc blade specification: D320×d200×T15mm

5. Disc blade material: 6CrW2Si, quenching hardness HRC58-60°

6. Slitting power: DC 75kw with reduction box and universal joint

7. DC motor controller: Euro-therm controller

8. Slitting power: 2.2kw cycloidal motor coordinate with worm and gear box

9. Blade replace type: hydraulic cylinder push rear cassette, cylinder specification: Φ63×450mm

10. Slitting speed: 0-120m/min adjustable

Scrap recoiling:

1. Type: double side recoiling

2. Recoiling disc specification: Φ450×350mm

3. Recoiling disc power: cycloidal motor driving separately on two side

4. Cast type: hydraulic cylinder push the recoiling pole to contract

5. Winding type: hydraulic cylinder drives winding poles moving back and forward

Accumulator:

1. Type: Concrete potting, double-side turnover platform

2. Accumulator size: 4m×2m×5m

3. Turnover plate structure: square pipe welded, sliding rolls on two sides, hard-wearing plastic plate on surface

4. Turnover motion: hydraulic cylinder lift, Φ80×500mm

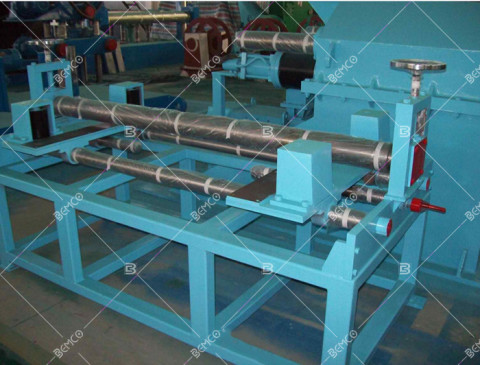

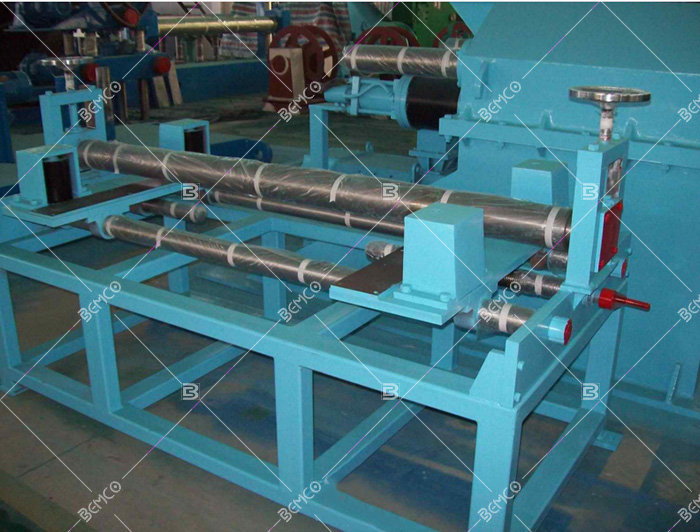

Distributing and damping:

1. Distributing shaft specification: Φ95×1400mm

2. Distributing plate specification: Φ200×3mm, 65Mn quenching

3. Place distributing plate type: manual push

4. Distributing shaft lift: hydraulic cylinder driving Φ75×100mm

5. Damping Type: Cassette beam press, wood plate and wool blanket between the up and down beam

6. Press power: hydraulic cylinder Φ80×150mm with 2 pieces, pressure adjustable

7. Leveling rolls specification: Φ320×1400mm, covered with rubber

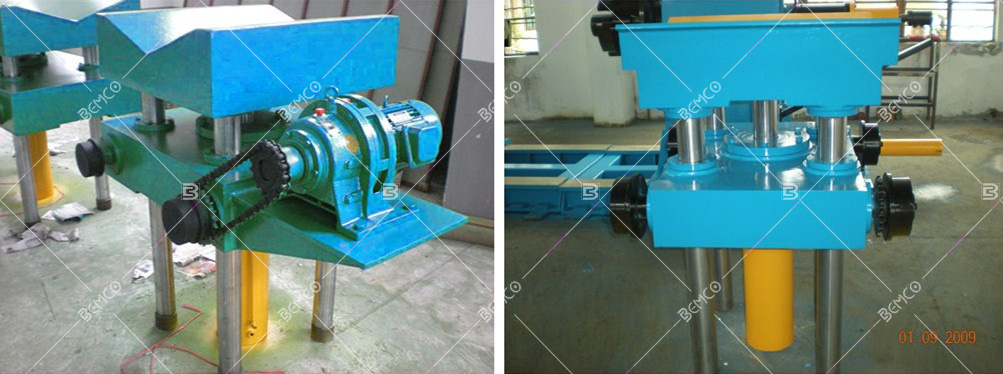

Recoiling and pressing:

1. Structure and type: Box type gear driving, hydraulic cylinder drives the sliding block to expand and contract

2. Recoiling shaft specification: Φ230×1400mm (recoiling block)

3. Recoiling block specification: Φ508×1400mm

4. Expand and contract power: cylinder specification Φ160×100mm

5. Recoiling shaft support frame structure: steel welded, hydraulic cylinder Φ80×350mm

6. Pressing shaft specification: Φ95×1400mm

7. Distribution disc specifications: 200*3mm, 65MN quenching

8. Distribution press power: Hydraulic Cylinder Φ75×350mm, pressure adjustable.

9. Recoiling power: 90KW DC motor

10. Controller: Euro therm controller

11. Recoiling speed: 0-120m/min adjustable

12. Max. Recoiling weight: 15000kg

Unloading car:

1. Structure and type: steel welded, 4-wheel moving

2. Driving power: BM3-195

3. Lift power: Hydraulic cylinder Φ180×700mm

4. Max. Weight: 15000kg

Hydraulic system:

1. Hydraulic station, control valve, oil pipe: each 1 piece

2. Pressure: 16Mpa

3. Power: 7.5KW-4

4. Oil tank volume: 450L

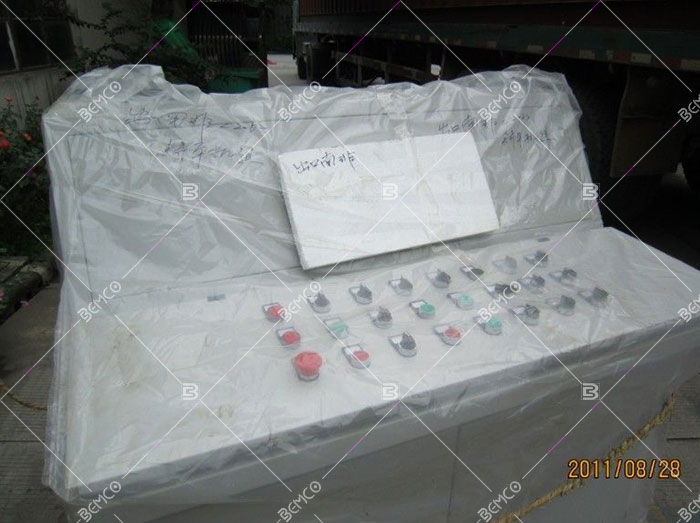

Electrical system:

1. Electrical control cabinet: 1 piece

2. Operating cabinet: 2 pieces

3. Total power: 175kw

Order Enquiry Form

Contact form description text