Multi-profile or size changeable roll forming machine is much helpful on the cost-saving .

In many of the industry , you will find the metal profile with many different sizes or maybe in different shapes. So is there any roll forming machine can change the forming shapes and sizes ?

As all known that the roll forming machine is custom designed for certain section of profile,so usually the roll forming machine is fixed type that only can make one size and one shape of product. But sometime , we can design a multi-functional roll forming machine if the shapes and sizes of the product is regularly changes. Such like our multi-functional purlin roll forming machine, it can change the roll forming shapes from section “C” to section “Z” ,”M” and “U” with out changing the roll toolings.And it also can change the sizes of the roll forming sizes in a range. We called the interchangeable type roll forming machine. It’s easy to find the connecting of the four shapes . If you are not sure about if these shapes can be roll formed by only one multi-functional roll forming machine, contact us and get the advice in 24 hours!

Beside of the interchangeable type roll forming machine, we also have another way to change the roll forming shapes to another. That will be the cassette type . The cassette type is one of the advanced technical common used in roll forming . The cassette system share the same roll forming machine base and power transmission system, the roll forming tooling and cutting system will be rapid change in minutes to switch the producing metal profiles to another.

Sometimes even the same shape of product , there are many different sizes, it will cost much if you buy machines for each size of product. That’s why you need Bemco .

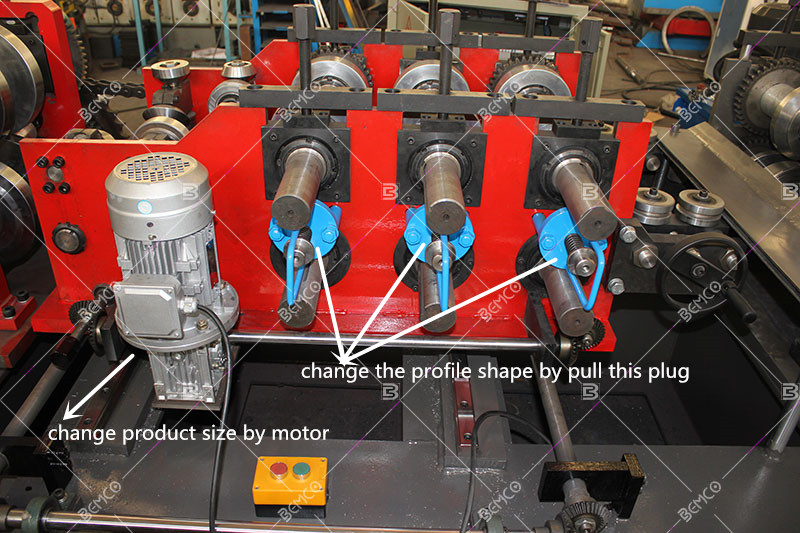

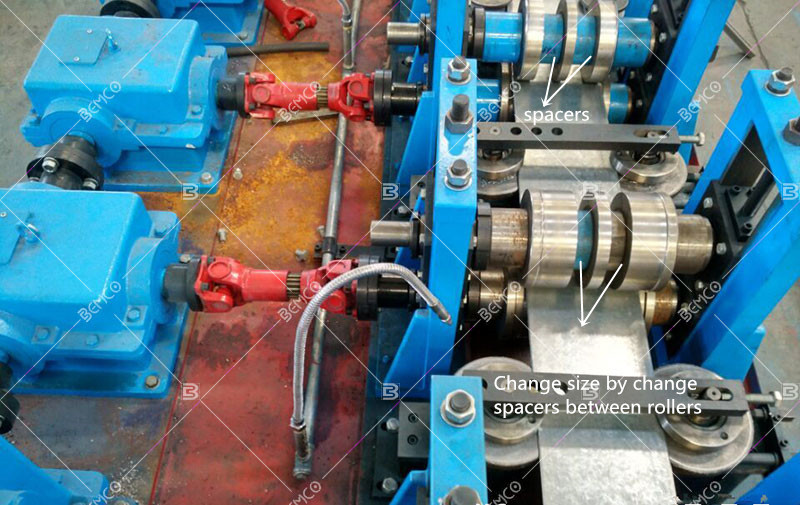

We can design the size changeable roll forming machine for the product have regularly sizes. We have two kind of ways to achieve that: manual change by spacers in roll toolings and automatic change by servo motor. To choose which is the best way for the roll forming machine, it will depends on how many product sizes there are. For the convenience of the operator , the automatic type will be more easier to change the sizes. If there are only few sizes that you have to change , like there are total 3 sizes of the roll forming product, you better choose the manual spacer type , because it will be more cost-effective ! Anyway , lean more by visiting our website www.bemcomachinery.com