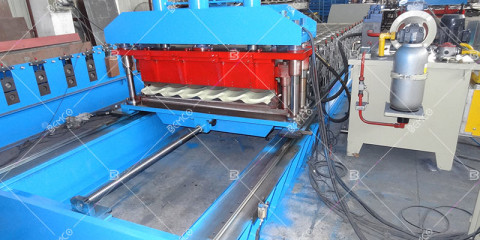

Metal siding wall panel roll forming machine brief.

The metal siding wall panel roll forming machine is a production line that dedicated on the manufacturing of metal sheet and panel for facade siding or cladding .

The metal cladding roll forming machine is an important family of wall panel roll forming machines.The wall panel can be divided into two kinds , one is for the Interior and the other is for Facades, and for most of application, the metal sheet and panel must be concealed fastener .

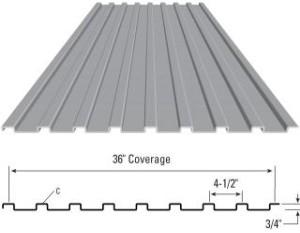

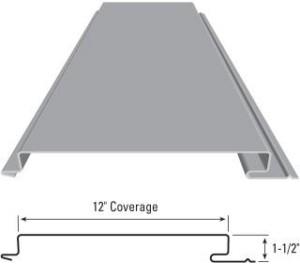

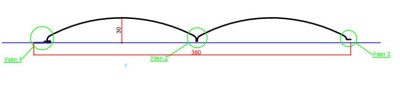

The standard profile drawing for metal siding wall panel roll forming machine

Exposed-fastener-type

Concealed fastener type

The metal siding wall panel roll forming machine is featured:

- Working with galvanized ,pre-painted or aluminum light gauge 0.4-0.6 mm

- Fully “hands-free”automatic control by PLC system with touch screen

- Cut to any length presetting in the program system

- Followcutting is optional with certain type of metal wall panel

- Auto-stacker is optional to save labor cost

- Perforated press is optional for the holes on the wall panel

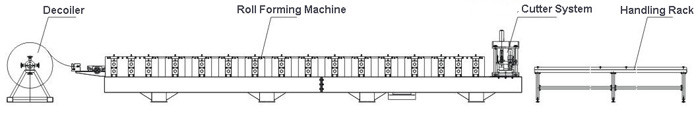

The metal cladding roll forming process :

Decoiling—guiding&leveling —roll forming—-hydraulic cutting—-stacking

Layout of metal siding wall panel roll forming line

| Machine Component | quantity |

| Decoiler | 1 set |

| Guide & pinch rollers | 1 set |

| Main forming machine | 1 set |

| Hydraulic cut device with hydraulic station | 1 set |

| PLC Control system | 1 set |

| Run out table | 2 sets |

Metal log siding roll forming machine parameter

| Suitable material | Coil type | Color Steel, Galvanised |

| Coil Thickness | 0.4-0.6mm | |

| Coil Width | Customized 914-1250mm | |

| Yield Strength | 250-350Mpa | |

| Decoiler | Decoiler Type | Manual or hydraulic |

| Weight Capacity | 5 Ton | |

| Main Roll Former | Forming Station | 13-20 forming stations, depend on profiles |

| Roller Material | High grade 45# steel, surface with hard chrome 0.05mm | |

| Shaft Material | #45 steel quenched 55-60 degree | |

| Shaft Diameter | 76 mm | |

| Drive Type | Chain Drive | |

| Forming Speed | 0-8 m/min (non-stop follow cutting) | |

| Main Power | 7.5 KW | |

| Cutting Device | Cutting Type | Hydraulic cutting |

| Cutting blade material | Cr12 with heat treatment | |

| Cutting Tolerance | +/-1.5mm(3m) | |

| Electrical System | PLC Brand | Panasonic brand |

| Inverter Brand | Yaskawa | |

| Encoder | OMRON brand | |

| Touch Screen | MCGS Chinese famous brand | |

| Electrical parts | Schneider | |

| Motors Reducer | Tailong and Guo mao Chinese famous brand | |

| Hydraulic System | Hydraulic Station | Famous Chinese Brand |

| Hydraulic Power | 4KW with 12 Mpa pressure | |

| Run out table | Table Type | No power passive with rollers |

| Function of Table | To support the profile sheets after cutting | |

| Machine | Dimension | 6500mm*600mm*800mm Around 4500kg |

| Tolerance | Length | 3M+/- 1.5mm |

Metal log siding roll forming machine ( Picture origin taken in factory)

Order Enquiry Form

Contact form description text