Hydraulic Arc Crimping Machine,Roof Panel Curving Machine brief.

The roof panel curving machine is a equipment for the arc crimping of the roll formed roof panel . It is a simple device work with roof panel roll forming machine to make the bullnose or the arch building panels.

The roof panel curving machine is special designed according to different roof panel profile, the working direction can be vertical or horizontal, we have the hydraulic arc crimping machine featured with the rotary type , it can change the working direction when needed, it is all controlled on the control panel , and it is fully automatic .

The common type of roof panel crimping machine is for R panel and corrugated panel, because they are very popular on the bullnose edge arch building on the roof .

The solutions on the roof panel crimping is consist of two components, the roof panel curving machine ,control panel and hydraulic station. it is all special designed for panels. It only can curving one type of roof panel.

The roof panel curving machine is featured :

- Automatic control by PLC system

- Hydraulic power shear device ,cut to any length

- The curving panel thickness range from 0.3mm- 0.8 mm

- Working with roof panel roll forming machine

- Max bending angle is 120

- Rotary type is optional to change the working direction

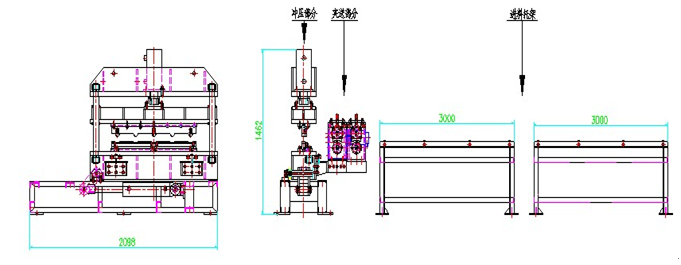

The roof panel curving machine technical drawing :

The working process of the roof panel crimping :

The arch bullnose is all starts from the metal roof panel that roll formed from roof panel roll forming machine , feeding the roof panel into hydraulic power curving equipment , then it will automatic curve the roof panel according to the client’s design , and then run out conveyor table .

Roll formed roof panel—guiding&feeding —crimping and curving—-stacking

The main technical parameter of roof panel crimping machine:

| Suitable material | Material | Roll formed roof panel |

| Panel thickness | 0.3-1 mm | |

| Panel width | Max 1000mm | |

| Curving | Curving speed | 0-10m/min |

| Roller material | High grade #45 steel , surface with hard chrome 0.05mm | |

| Shaft Material | #45 steel quenched 55-60 degree | |

| Shaft Diameter | 75 mm | |

| Drive Type | Chain Drive | |

| Curving rollers | 2 sets according to profile | |

| Main Power | 1 KW | |

| Curving die material | Cr12 heat treated | |

| Electrical System | PLC Brand | Panasonic brand |

| Inverter Brand | Yaskawa | |

| Encoder | OMRON brand | |

| Touch Screen | MCGS Chinese famous brand | |

| Electrical parts | Schneider | |

| Motors Reducer | Tailong and Guo mao Chinese famous brand | |

| Hydraulic System | Hydraulic Station | Famous Chinese Brand |

| Hydraulic Power | 4 KW with 12 Mpa pressure | |

| Machine | Dimension | 1900mm*1700mm*1200mm Around 1500kg |

| Tolerance | Length | 3M+/- 1.5mm |

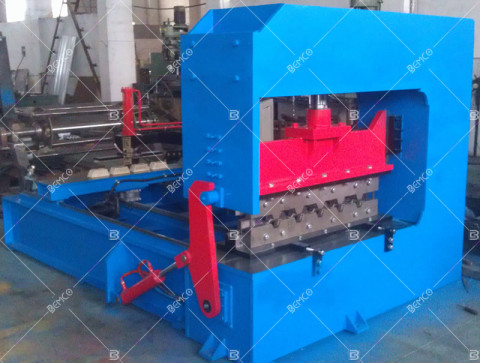

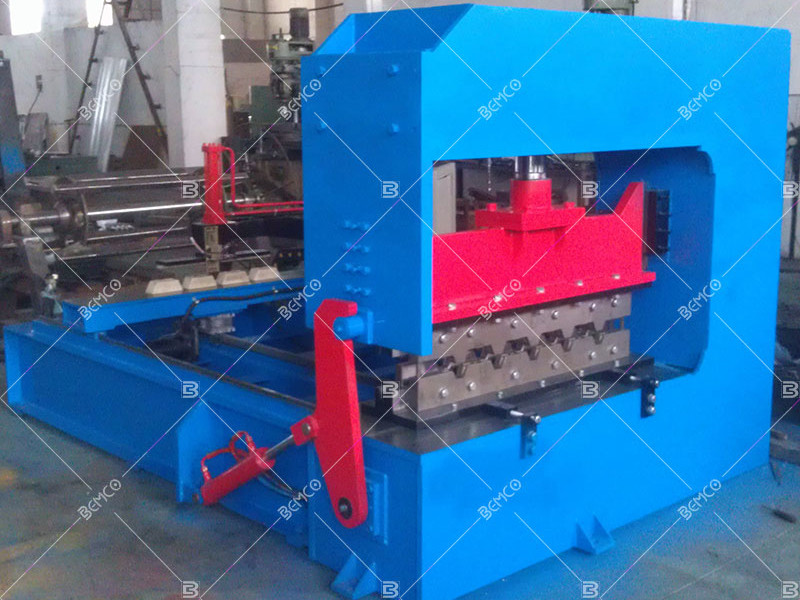

Hydraulic arc building panel curving machine ( Picture origin taken in factory)

Order Enquiry Form

Contact form description text